Best Pool Coping Guide for New Jersey (2025): What Actually Survives Freeze–Thaw

Marble coping with a submerged marble wall detail and matching tile for a seamless architectural transition.

NJ homeowners — we live in the Northeast.

If your coping can’t handle freeze–thaw, it fails. Period. Here’s the playbook that won’t.

TL;DR — NJ / Northeast Coping Rulebook

2" thick minimum. Heavier is often better.

Engineer coping + beam first.

Plan drainage day one.

Match material to architecture + climate.

Budget for edges + handling.

Longevity lives or dies on waterproofing, installation, and grout.

Maintain with smart sealing + seasonal care.

“Some of this may sound like basic 101, but I’ve been called in to fix plenty of projects where these rules were ignored.”

Why Location Decides Your Coping

Freeze–thaw moves the ground.

Structural engineering should be designed to withstand those shifts.

Civil engineering should be design to get the water away. Ice is the enemy.

Proper design, material selection & installation protect the interface so ice, buildup, and water never penetrate. That’s how coping survives through movement, moisture, and time.

The Thickness Rule

2-inch minimum. Heavier often better.

That added mass anchors the edge, provides stability, and absorbs minor surface movement through seasonal change.

It’s not just about visual it’s about weight.

Pro Tip: If you really want thin, drop-face porcelain, it can work in mild climates. But here in the frost belt, it adds joints, risk, and maintenance you don’t need. I prefer a heavier material. You’re in the frost belt, build like it.

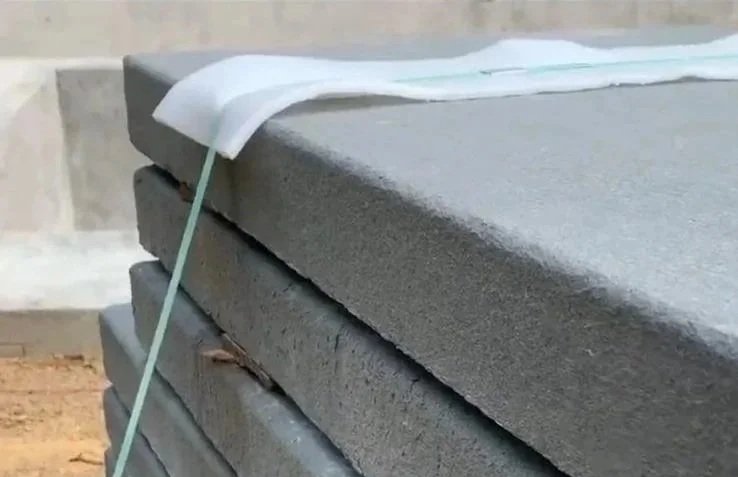

Custom 3" bluestone coping with an eased edge, staged and ready for installation.

Elevation Is Everything

Your coping height sets the datum for the entire project. Get it wrong, and you’ll fight water forever.

Again, it sounds basic, but I’ve fixed countless coping failures from negative pitch, it happens more than you’d think.

Coordinate early:

Coping + beam with cover tracks, raised walls, and edges.

Set positive-pitch drainage away from the pool.

Align patio and landscape grades for seamless visuals and clean water flow.

Done right, coping elevation dictates how everything ties together, structurally and civilly.

Material Choices (Form + Function)

This is where design meets reality.

Your coping isn’t just a trim piece, it’s the visual and functional bridge between the water, the structure, the hardscape and the landscape.

It defines the edge you see, the surface you walk on, and the transition that protects everything beneath it.

Match architecture:

Material selection sets the tone for the entire space: proportion, color, and texture all communicate the architectural and design intent.

Keep in mind this selection will also determines how your pool performs through the seasons. The wrong material can look beautiful for a year, then fail under freeze-thaw or constant exposure. The right one feels timeless, performs flawlessly, and requires little more than routine care.

Design intentionally: contrast on purpose, not by accident. Choose tones and textures that complement existing masonry or exterior finishes.

Safety + comfort:

Light materials: stay cooler underfoot but show more dirt and require more maintenance.

Dark materials: warmer, more forgiving, and provide visual grounding (for example, bluestone).

Custom eased-edge limestone coping installed on a raised beam with a sheer descent, combining precision detailing with smooth water flow.

Cost Drivers (So You’re Not Surprised)

This is where the numbers can start to move.

Coping is one of those line items that can look simple on paper but shift dramatically once size, detail, and site conditions come into play.

Thickness and width are the first drivers.

A standard 12-inch-wide, 2-inch-thick coping is common, but step up to a 18”, 24”, or even a 36” -inch “estate-width” or “Hampton’s style” coping, and you are significantly increasing the material volume and the handling weight.

Lengths and layout matter, too.

The desired piece length and pattern layout, whether you want clean, long runs with minimal joints or a more modular pattern, directly affect fabrication and waste.

For example, asking for longer than standard coping units looks elegant and reduces joint lines, but requires larger raw slabs, higher cutting precision, and specialized handling. Shorter modules may lower waste but increase visible joints and labor during placement. The goal is to find a layout that balances appearance, availability, and efficiency.

Longer and Heavier pieces require more labor, more equipment, and more precision in setting. That’s before edge fabrication even begins.

Then come site variables and specialty features.

Pools with automatic cover vaults, raised walls, or infinity edges often require additional engineering and structural reinforcement. Access also matters: tight or sloped sites demand staging, crane lifts, or custom delivery methods, all of which affect cost.

The smartest approach:

Select your top two coping materials, then work backward from your site conditions, grading, fabrication and maintenance realities. This approach gives you flexibility without surprises, and ensures the aesthetic you choose aligns with how the project actually needs to be built.

Edge profiles

A standard rock face may be included, but an eased edge, bullnose, bevel, or custom hand-finished edges are typically an upgrade.

Edge profiles aren’t just aesthetic, they’re functional.

They help define the architectural motif and express the design intent. Hard edges on certain materials can look sharp and modern, but they can also be abrasive when getting in or out of the pool. A bullnose edge, on the other hand, offers a smoother, more traditional look that’s comfortable under hand and foot, especially for families with children. The goal is to select an edge that aligns with the design language of the project while also enhancing safety and usability.

Fabricator visit with a client to see their custom 24” limestone coping in production and finalize their eased edge selection.

Durability, Heat, and Maintenance

Once the design and installation are done, what lasts comes down to material behavior and care.

Every stone or surface tells a different story in the Northeast. How it handles heat, water, and wear determines how it will look ten years from now.

Material personalities:

Granite: the hardest and most dense. Extremely durable and resistant to chipping.

Limestone: softer and more porous. Delivers a refined, classic look that pairs beautifully with traditional architecture.

Bluestone: the regional workhorse. Strong, timeless, and available in multiple finishes.

Marble and porcelain: sleek, modern, and crisp. Both can perform well when properly detailed.

Thermal comfort matters.

Light materials stay cooler but reflect more glare. Darker tones absorb heat yet hide footprints, debris, and wear better. Consider how the space will be used — barefoot lounging, daytime entertaining, or evening ambiance — and choose accordingly.

Maintenance is simple, but not optional.

Use low-pressure washing and pH-neutral cleaners, avoid acid wash (unless with a professional for certain use case).

Inspect joints seasonally; frost and UV exposure can degrade grout and sealant over time.

Your first step in long-term durability is correct material selection and proper installation.

Do that right, and your coping becomes part of the architecture, aging gracefully, not deteriorating.

Durability isn’t luck; it’s the result of engineering, detailing, and stewardship.

And that’s why it’s critical to work with a professional who can tie all of these layers together, from design intent, to structural integration, to the final installation, & maintenance.

A seasoned professional can anticipate how the structure, drainage, finish materials, and environment interact, ensuring that your coping performs beautifully for decades, not just looks good on day one

Note: Insights are educational, not guarantees. Design and cost outcomes vary by project and require licensed review for verification.